Sostenibilidad

Los materiales de construcción con emisiones negativas de carbono podrían reemplazar al hormigón

Securities.io mantiene rigurosos estándares editoriales y podría recibir una compensación por los enlaces revisados. No somos asesores de inversiones registrados y esto no constituye asesoramiento de inversión. Consulte nuestra divulgación de afiliados.

El coste medioambiental del hormigón tradicional

Al examinar el sector de la construcción actual, es evidente que el hormigón es uno de los materiales más utilizados. La mayoría de las nuevas construcciones se basan en él debido a su asequibilidad, disponibilidad y flexibilidad.

Estadísticas del mercado del hormigón

El mercado mundial del hormigón está valorado actualmente en 402.87 millones de dólares, superando al mercado estadounidense de cemento. $ 15.22B solo en 2025. Esta demanda provino de varias fuentes, incluidos proyectos de infraestructura gubernamental como carreteras y autopistas, que representaron el 11% de la demanda.

Los centros de datos fueron otra razón para la reciente expansión del mercado del hormigón. Según (aqui)Los centros de datos representaron 247,000 toneladas de hormigón en 2025, y los analistas predicen un crecimiento aún mayor en este sector en 2026.

La construcción moderna es un desperdicio

Han salido a la luz varios problemas relacionados con la creciente demanda de materiales de construcción de hormigón. En primer lugar, el proceso es muy perjudicial para el medio ambiente. Según informes, la construcción con hormigón representa el 8 % de las emisiones globales de CO2. Lamentablemente, el método de fabricación actual consume mucha energía, ya que requiere que el hormigón se hornee a altas temperaturas durante su proceso de curado, que dura semanas.

Tecnologías de Construcción Sostenible

Reconociendo la necesidad de lograr un equilibrio y la sostenibilidad, los ingenieros han dedicado incontables horas a encontrar maneras de crear tecnologías de construcción sostenibles. Estas estrategias abarcan una amplia gama de enfoques, desde el uso de biomateriales hasta diseños revolucionarios que requieren menos materiales para su realización.

Fuente - WPI

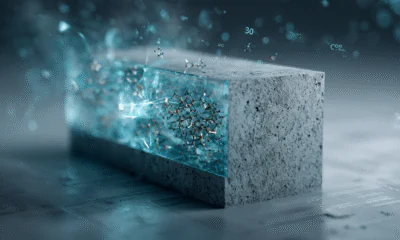

Uno de los métodos más interesantes que los ingenieros han buscado para reducir los efectos de la fabricación de hormigón es el uso de andamios a base de hidrogel. Este tipo de hormigón le permite resistir la erosión hídrica y evitar filtraciones peligrosas en el agua.

Problemas con las tecnologías de construcción sostenible en la actualidad

En la última década, se han producido avances en la investigación para reducir el impacto ambiental de la fabricación de hormigón. Sin embargo, hasta la fecha, la mayoría de los enfoques han requerido métodos de fabricación complejos e inescalables, o al menos algún recubrimiento o capa protectora adicional. Esta falta de resultados llevó a muchos investigadores a pensar que era casi imposible crear materiales de construcción con emisiones de carbono negativas mediante métodos de bajo consumo energético.

Resultados del estudio de WPI: Materiales enzimáticos vs. hormigón

Desliza para desplazarte →

| Métrico | Concreto Tradicional | ESM (sumidero de carbono) |

|---|---|---|

| Emisiones de CO₂ (kg/m³) | ~ 330 kg | ~ 6 kg |

| Fuerza compresiva | 20–25 MPa | 25.8 MPa |

| Hora de curar | 28 días | Horario: |

| Captura de carbon | Ninguna | Carbono negativo |

Afortunadamente, los investigadores del WPI no recibieron el memorando. El “Materiales estructurales enzimáticos carbono-negativos duraderos y de alta resistencia mediante una técnica de suspensión capilar ¹” Un estudio publicado en la revista científica Matter explica cómo el equipo pudo crear materiales de construcción que retienen carbono utilizando formaciones compuestas de mineralización catalizada por enzimas.

Mineralización catalizada por enzimas

En concreto, el equipo creó una mezcla enzimática específica junto con una estrategia de suspensión capilar que les permitió capturar minerales de calcio precipitados dentro de una matriz de carbono. Una vez entrelazadas en la matriz, las partículas se unen de forma natural.

Material estructural enzimático (ESM)

Este enfoque elimina la necesidad de métodos de curado artificial, como la cocción en hornos a altas temperaturas. Además, crea un material moldeable que proporciona una resistencia estructural comparable a la de las alternativas de hormigón. La base de esta tecnología es el uso de estrategias de curado térmico para crear de forma natural compuestos ternarios con puentes de CaCO₃ con porosidad y propiedades mecánicas ajustables.

Captura de CO2

Además de ser más fácil de fabricar y menos perjudicial para el medio ambiente, el ESM tiene otra gran ventaja: funciona como un sumidero de carbono. Los sumideros de carbono atrapan el CO2, lo extraen de la atmósfera y lo almacenan.

Fuente - Celular

Sorprendentemente, el ESM cuenta con enzimas que solidifican el CO2 y lo convierten en material más sólido. Esta estructura de captura de carbono le otorga una gran ventaja en términos de impacto ambiental. Su diseño carbono-negativo y su capacidad de sumidero hacen que este material cumpla plenamente con las directrices ambientales de la ONU para un futuro sostenible.

Prueba de materiales de construcción con sumideros de carbono

Nima Rahbar y su equipo probaron su nuevo material para determinar su resistencia, durabilidad, hidrorresistencia y capacidad de captura de carbono. También probaron la resistencia del material después de moldearlo en diferentes formas y mediante diversos procesos, lo que permitió al equipo perfeccionar su enfoque.

Resultados de las pruebas del estudio sobre materiales de construcción que absorben carbono

Los resultados del estudio fueron positivos. Sorprendentemente, el ESM superó al hormigón en cuanto a resistencia hidroeléctrica. Además, los informes demostraron que el material, con una microestructura de hidrocarbón, superó al hormigón tradicional en resistencia estructural.

En concreto, el material registró una resistencia a la compresión media de 25.8 MPa. Esta puntuación sitúa a estos materiales por encima de las capacidades actuales de otras alternativas de construcción sostenible, como los materiales de construcción vivos (LBM) y los materiales de construcción vivos de ingeniería (ELM).

Los ingenieros también observaron que el método de producción era mucho más ecológico que el hormigón tradicional. La creación de un metro cúbico de ESM produjo solo 6 kg de CO2, en comparación con los 330 kg necesarios para crear una cantidad similar de hormigón tradicional.

Ventajas de los materiales estructurales enzimáticos (ESM)

El ESM aporta una larga lista de beneficios al mercado. Por un lado, ofrece una alternativa comparable al hormigón tradicional, que, gracias a su uso generalizado, ya cuenta con una amplia infraestructura y profesionales que ahora pueden utilizarlo sin realizar grandes modificaciones.

El ESM proporciona mayor resistencia gracias al proceso de unión de partículas y curado empleado en este diseño. Además, cura mucho más rápido que el hormigón. Las opciones tradicionales necesitan al menos 28 días para curarse correctamente. En comparación, el ESM cura en pocas horas, lo que permite una rápida construcción y reparación.

Económico

Existen también razones financieras que hacen que el ESM se considere un hito importante en el sector. Por un lado, reduce la mano de obra requerida durante el proceso de fabricación. Además, su reparabilidad implica menores costos de mantenimiento. Asimismo, la alta moldeabilidad de este material reduce los residuos de construcción, lo que a su vez reduce los costos de construcción y prolonga la vida útil de los proyectos.

Global

Otra gran ventaja del ESM es su escalabilidad y producción a nivel industrial. Ofrece resistencia y moldeabilidad comparables, además de menos desperdicio. Todos estos factores se traducen en mayores ingresos para los fabricantes de hormigón y mayor calidad para quienes utilizan los materiales.

Ecológico

Al analizar el panorama general, el ESM ofrece una alternativa viable al hormigón tradicional. Es respetuoso con el medio ambiente. Su diseño como sumidero de carbono podría ayudar a combatir el cambio climático y reducir el impacto en ciudades, carreteras y otros ámbitos.

Además, el material se diseñó desde el principio para ser reciclable. El objetivo es crear un proceso de fabricación circular. De tener éxito, ESM podría ser fundamental para sustentar proyectos de vivienda asequible, infraestructura y mantenimiento en el futuro.

Cronograma comercial del hormigón con emisiones negativas de carbono

Existen numerosas aplicaciones para la gestión ambientalmente racional (EMA) en el futuro. Por ejemplo, se podría ver su uso en futuras infraestructuras y proyectos de construcción a gran escala. La integración de materiales que capturan carbono ayudará a reducir el impacto de la expansión humana y la disminución de los bosques.

Cabe destacar que las carreteras son una de las principales causas de emisiones de CO2. Desde los métodos de fabricación del asfalto y el hormigón hasta su construcción, e incluso los vehículos que circulan por ellas, cada paso produce más CO2. El uso de ESM crearía carreteras que ayudarían a atrapar el CO2 de los vehículos, reduciendo así las emisiones.

Cronograma de comercialización y perspectivas de adopción

El ESM podría implementarse en los próximos 5 años. Aún se requieren más pruebas antes de que este material sea aceptado en grandes proyectos de infraestructura. Sin embargo, se alinea con la Carta de Carbono Neto Cero de la ONU y ofrece una fabricación más asequible con un menor impacto ambiental. Por lo tanto, es probable que esta tecnología tenga una demanda masiva.

Investigadores de materiales de construcción que absorben carbono

El estudio sobre la construcción de sumideros de carbono fue dirigido por científicos del Instituto Politécnico de Worcester (WPI). En concreto, Nima Rahbar, profesor de la Facultad de Ingeniería Civil, Ambiental y Arquitectónica de la Universidad Ralph H. White, figura como responsable de esta investigación. El artículo también incluye a Shuai Wang, Pardis Pourhaji, Dalton Vassallo, Sara Heidarnezhad y Suzanne Scarlata como miembros colaboradores.

El futuro de los materiales de construcción que absorben carbono

El equipo se centrará ahora en conseguir socios de renombre en la industria para ayudarles a escalar su proceso de fabricación de ESM. Este paso les obligará a analizar en profundidad cómo mejorar las propiedades mecánicas, la durabilidad y la eficiencia de los ESM.

Exposición del mercado público a la construcción sostenible

Diversas empresas han invertido millones en investigación para encontrar mejores alternativas a las tecnologías de construcción actuales, que generan desperdicio. Estas empresas entienden que la sostenibilidad es clave para garantizar la prosperidad futura. Aquí presentamos una empresa que impulsa continuamente la innovación y se mantiene como una empresa de renombre en el sector.

CRH (CRH)

Si bien las soluciones de laboratorio como ESM están en sus inicios, el gigante de la industria CRH es el que tiene más probabilidades de expandirlas. Como empresa líder en materiales de construcción en Norteamérica, CRH ha ido mucho más allá del hormigón tradicional a través de su Fondo de Emprendimiento e Innovación de 250 millones de dólares.

Cabe destacar que CRH se ha asociado con Carbon Upcycling Technologies (CUT) para implementar la captura de carbono a escala comercial. En julio de 2025, la filial Ash Grove de CRH inició la construcción de una instalación pionera en su tipo en Mississauga, Ontario, diseñada para capturar CO2 directamente de hornos de cemento y mineralizarlo en materiales de construcción. Esto se alinea directamente con los principios de sumideros de carbono demostrados en el estudio WPI.

Al invertir en nuevas empresas a través de su acelerador “Materiales de construcción sostenibles”, CRH actúa como un puente entre los avances académicos y la realidad industrial, convirtiéndose en una apuesta “a pulso” para la descarbonización de la infraestructura.

CRH plc (CRH -0.46%)

Cabe destacar que CRH ha comenzado a mostrar cierto movimiento positivo en 2026, pasando de $125.51 a $131.38 el 9 de enero de 2026. Actualmente, tiene una media móvil (MA) de 50 días que muestra una postura alcista que está en línea con sus ganancias anuales actuales del 31%.

Últimas noticias y rendimiento de CRH (CRH)

Armor Advisors LLC reduce su participación en Crh Plc $CRH

CRH plc: Sobrevaloración en 2026

CRH plc: Enfoque en el crecimiento internacional e inorgánico

Aspectos destacados de la conferencia telefónica sobre resultados del cuarto trimestre de 2025 de CRH PLC (CRH): resultados financieros récord e iniciativas de crecimiento estratégico

Transcripción de la conferencia telefónica sobre los resultados del tercer trimestre de 4 de CRH plc (CRH)

Las ganancias del cuarto trimestre de CRH cumplen con las estimaciones, los ingresos aumentan interanualmente y las acciones bajan.

Materiales de construcción que absorben carbono | Conclusión

Sorprendentemente, el arduo trabajo y la dedicación del equipo podrían generar un cambio radical en el mercado. Si tan solo el 1% de la construcción mundial se desplaza hacia materiales con emisiones de carbono negativas como el ESM, podría impulsar el mercado al siguiente nivel, reduciendo al mismo tiempo las emisiones de CO2 en el futuro.

Al considerar la mayor sostenibilidad, la reducción de costos y la modularidad, es fácil imaginar un futuro en el que los fabricantes prefieran trabajar con ESM en lugar del hormigón tradicional. Todos estos factores, combinados con un curado más asequible y rápido, una resistencia ajustable y la reciclabilidad, podrían impulsar su adopción en el futuro.

Conozca otros proyectos de sostenibilidad que cambian el juego aqui.

Referencias

1. Wang, S., Pourhaji, P., Vassallo, D., Heidarnezhad, S., Scarlata, S. y Rahbar, N. (2025). Materiales estructurales enzimáticos carbono-negativos duraderos y de alta resistencia mediante una técnica de suspensión capilar. Matter, 102564. https://doi.org/10.1016/j.matt.2025.102564