Sustainability

AI Advances Thin-Film Solar by Unlocking Perovskite Stability

Securities.io maintains rigorous editorial standards and may receive compensation from reviewed links. We are not a registered investment adviser and this is not investment advice. Please view our affiliate disclosure.

From Silicon To Thin Films

In our article “The Solar Age – A Bright Future To Mankind“, we explained how the rise of solar energy was ushering in a revolution in our energy supply, at least in the long term.

So far, around 90% of solar panels are made using silicon-based technology, with the large majority using polysilicon designs, which have replaced the monosilicon older designs (monocrystalline silicon is more durable, but also less cost-efficient).

Source: EIA

An alternative is perovskites, also often called thin-film solar cells, which capture the Sun’s energy thanks to the unique crystalline structure of perovskite. (Another form of thin film solar technology uses cadmium telluride thin film cells.)

The term thin film comes from the much thinner layer of material required for producing electricity, making for more flexible and lighter solar cells.

Naturally occurring perovskites are made of calcium and titanium oxide (CaTiO3), but other minerals can have the same crystalline structure with a chemical formula following an “ABX3” rule.

While very high in their energy conversion yield, perovskites are less durable than silicon solar cells, which have hindered practical use and their commercial adoption.

Researchers at the Chalmers University of Technology (Sweden) and the University of Birmingham used machine learning to clarify the missing part of theoretical knowledge about perovskite crystal structure, opening the way to make them more durable, and therefore, maybe the next generation of commercial photovoltaic technology.

They published their results in the Journal of the American Chemical Society1, under the title “Revealing the Low-Temperature Phase of FAPbI3 Using a Machine-Learned Potential”.

Formamidinium Perovskite Stability

The researchers worked with a material called formamidinium lead iodide (FAPbI3). It is considered one of the best-performing materials in the halide perovskite group for its promising properties for future solar cell technologies.

However, the material is generally not stable enough under sunlight for commercial application, and part of the reason is that the low-temperature phase of formamidinium lead iodide remains poorly understood, until now.

“The low-temperature phase of this material has long been a missing piece of the research puzzle and we’ve now settled a fundamental question about the structure of this phase.”

Advanced AI Modeling

Experimental observations had so far not been enough to understand the FAPbI3 crystal structure. Traditional computer simulations, trying to calculate and simulate the behavior of the atoms one by one, require powerful supercomputers and long simulation times.

Instead, the researchers used their expertise in machine learning to drastically improve the efficiency of computer simulation.

“By combining our standard methods with machine learning, we’re now able to run simulations that are thousands of times longer than before.

And our models can now contain millions of atoms instead of hundreds, which brings them closer to the real world,”

Crystal Phase Transitions in FAPbI3

Depending on temperature, FAPbI3 can take different crystal structure: cubic at 300°K (27°C / 80°F), tetragonal below 285°K (12°C / 53°F) and still unknown at 140°K (-133°C / -207°F)

They found that their simulation predicted that the material can be put into a semi-stable state when cooled.

They then tested it in real life -200 °C / -328°F, to confirm that the simulation accurately predicts the behavior of perovskite crystals, especially in this yet unproven condition.

The model mostly worked with almost perfect prediction for the movement of carbon atoms, and an accurate enough prediction for nitrogen atoms.

Applications of AI-Powered Perovskite Research

This model is the first one to predict with good accuracy all the crystal structures of this perovskite material. It is also a lot less intensive in terms of compute requirements, making it usable by almost any research team in the world. So it might drastically speed up the progress of this technology.

Crystal structure and their stability are the keystones to make perovskite more durable, and so is also key to making them commercially viable.

“We hope the insights we’ve gained from the simulations can contribute to how to model and analyse complex halide perovskite materials in the future,”

Thin-film solar, being more flexible, can be deployed in many more contexts than traditional solar panels. They are also a lot lighter in weight.

So if perovskite can be used commercially, we could start using it on the surface of buildings, cars, rooftops, cell phones, etc, providing abundant energy without the need for dedicating land to large solar farms.

Amidimium seems the right direction for this technology, with other reports also indicating that a protective coating of amidimium can radically increase the life span of thin film solar cells. Alumina nanoparticles could also boost perovskite solar cell lifespan 10x.

Most likely, a combination of several of these technologies will emerge to create an ultra-durable thin-film perovskite solar cell.

Swipe to scroll →

| Technology | Material | Efficiency Potential | Durability | Commercial Readiness |

|---|---|---|---|---|

| Silicon (mono/poly) | Crystalline silicon | 22–26% | Very high (25–30 years) | Fully commercial |

| Cadmium Telluride | CdTe thin-film | 23–25% | High (30 years, 89% retention) | Commercial (First Solar) |

| Perovskite (FAPbI3, amidinium) | Halide perovskites | >30% (lab-scale tandem) | Currently low (degrades under sunlight) | Pre-commercial, research stage |

Investing in Solar Innovation

First Solar, Inc.

First Solar, Inc. (FSLR +1.85%)

First Solar is the largest solar panel manufacturer in the USA and in the whole Western hemisphere, with manufacturing sites in the US, Malaysia, and Vietnam.

The company is not using the classic crystalline silicon technology and instead uses its proprietary thin-film photovoltaics.

Based on cadmium-telluride, they are more efficient, are produced at a lower cost, and can easily be mass-manufactured.

Source: Department Of Energy

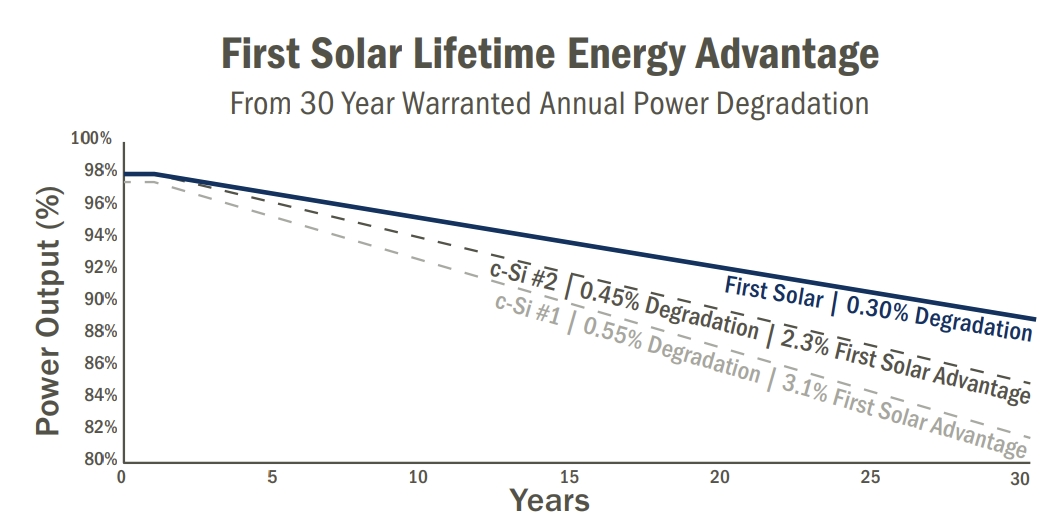

Cadmium telluride thin-film solar panels are also more durable, retaining 89% of the original performance after 30 years.

Source: First Solar

Cadmium and telluride are byproducts of the mining for other metals, which means that First Solar products have a minimal impact, using resources that were of little use before. Thin-film panels can also have a high recycling rate.

The company’s focus on thin-film semiconductor technology allows it to be fully vertically integrated, making it radically different from the silicon-based solar panel industry.

Instead of multiple factories, with each actor specialized in one segment like polysilicon purification, and with many days to produce a solar cell, First Solar can go from raw materials to finished product in less than 4 hours.

Source: First Solar

First Solar’s technological edge, combined with its geographical location, makes it the likely beneficiary of the growing push for Western countries to source their panels from outside China.

The company is ramping up its production capacity quickly, aiming to reach a nameplate capacity of 25 GW by 2026, from the current 11 GW.

First Solar has spent a cumulative $2B in R&D since its inception. R&D teams at First Solar forecast a thin film CdTe of 25% cell efficiency and pathways to 28% cell efficiency by 2030.

Considering its involvement in the research discussed here, the company is also clearly interested in perovskite, at least as soon as these panels are durable enough.

In the long run, First Solar is looking to integrate its experience with cadmium telluride thin film to perovskite technology, making the resulting solar panels even more efficient.

Source: First Solar

Overall, First Solar is a technology leader that stands to benefit from tariffs on Chinese imports, something likely to compensate for the negative effect on the solar industry from Trump’s reelection.

While mostly focused on thin-film solar using cadmium telluride for now, its expertise in non-silicon solar panel manufacturing could give it a significant head start with perovskite, especially considering its deep ties to some of the top researchers in this field.

(You can also read more information about First Solar in the investment report dedicated to the company)

Latest First Solar (FSLR) Stock News and Developments

First Solar (FSLR) Stock Declines While Market Improves: Some Information for Investors

First Solar, Inc. (FSLR) Is a Trending Stock: Facts to Know Before Betting on It

FSLR Stock Down 13.8% in Three Months: What's Next for Investors?

Poll Shows GOP Voters Support Solar Energy, American-Made Solar

First Solar, Inc. $FSLR Shares Purchased by National Pension Service

Chinese solar stocks rally on reports Elon Musk's Space X, Tesla staff visited suppliers

Study Referenced

1. Sangita Dutta, Erik Fransson, Tobias Hainer, Benjamin M. Gallant, Dominik J. Kubicki, Paul Erhart, and Julia Wiktor. Revealing the Low-Temperature Phase of FAPbI3 Using a Machine-Learned Potential. Journal of the American Chemical Society. August 14, 2025. https://pubs.acs.org/doi/10.1021/jacs.5c05265