Disruptive Tech

Advancing Sustainable Construction Through Technology

Securities.io maintains rigorous editorial standards and may receive compensation from reviewed links. We are not a registered investment adviser and this is not investment advice. Please view our affiliate disclosure.

From Traditional Construction to Digital Eco-Construction

Construction is generally a very energy- and labor-intensive activity, generating significant pollution. It is still primarily an “offline” activity, with little digitalization compared to other economic activities.

A scientific paper published in Sustainable Futures1 is looking at how the emergence of AI, blockchain technology, digital fabrication, and the trend toward sustainability might affect this industry.

Together, digital technologies and eco-materials could bring a significant acceleration to eco-construction technologies and reduce the environmental impact of the construction industry.

The study was done by Malaysian researchers at the Asia Pacific University of Technology & Innovation (APU) and the National University of Malaysia (UKM), published under the title “Digital integration in eco-construction 2.0: Advancing sustainability through technology”.

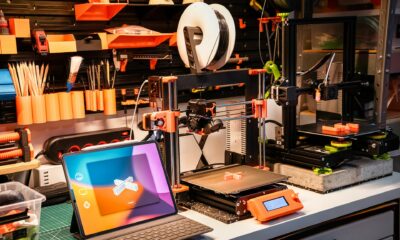

New Production Methods

Materials in construction have been historically mass-produced in standardized forms, and any assembly required skilled human labor. New technologies are likely to change this status quo in the near future.

The first ones are production methods beyond factory mass production with computer numerical control (CNC) machining, laser cutting, and 3D printing. Each has its own advantages and weaknesses, and should be picked depending on the requirements of a given task.

Source: Sustainable Futures

These methods significantly reduce the amount of material lost during the processing of raw material into finished goods for construction.

They also allow a much higher level of flexibility over the final design, making custom design more accessible.

Lastly, they can be manufactured at a much smaller scale and more locally, potentially leading to a drastic reduction of the footprint of transport of material from raw materials to the factory to construction sites.

“This methodology is not only conducive to utilizing eco-materials but also aligns closely with lean construction principles and net-zero goals due to its inherently low waste profile.“

All these new production methods benefit greatly from the improvement and democratization of computer-aided design (CAD) and the widespread adoption of Building Information Modeling (BIM). CAD and BIM form today the digital backbone of most construction projects.

Eco-Materials

Another change affecting the construction industry is the shift to more environmentally friendly materials.

A major driver of change is 3D printers capable of using materials such as recycled plastics, biodegradable polymers, and composite materials that incorporate natural fibers

In particular, geopolymers can be used in 3D printing. Geopolymers are inorganic, typically ceramic-like materials that can be made from industrial byproducts such as fly ash or slag, which are otherwise waste products from power plants and steel mills. It can be formulated from locally sourced materials.

By doing so, it puts the construction industry in a position to recycle industrial waste instead of consuming resources.

The development of large-scale 3D printers has enabled the construction of entire building structures directly on-site, reducing transportation costs and associated carbon emissions.

However, the cost of 3D printers and their relatively low speed should be noted as still serious limitations of this technology and slowing down its deployment at scale.

Renewable ecomaterials, like mass timber used for building wood skyscrapers, could also help reduce the carbon emissions and resource consumption of the construction industry.

New Designs

3D printed buildings can also adopt more complex custom shapes than buildings made from mass-produced elements.

As a result, it can facilitate the integration of natural and ergonomic forms into buildings, which can enhance energy efficiency through better thermal dynamics and light distribution.

The integration of natural isolation forms, such as honeycomb structures, enhances isolation while reducing material costs and can also increase the value of 3D printing in construction.

3D printing also enables the creation of “gradient materials,” where material properties vary across a single object to meet specific functional requirements without excess material use.

Blockchain for Sustainable Construction Supply Chains

Another recurring challenge of the construction industry is probably tracking the source of the materials used and their ESG profile.

This is a field where the efficient records allowed by blockchain technology can help.

By automating and securing transactions across the supply chain, blockchain not only enhances operational efficiencies but also builds trust among stakeholders by providing a clear and immutable record of material origins, processing, and transportation.

Blockchain can also be used to enable smart contracts, making execution of contracts smoother, putting the technology potentially at every step of the construction process, from sourcing materials to verification and certification of the finished building.

Source: Sustainable Futures

By helping track and prove the sourcing of materials used in construction, blockchain can help match the requirements of advanced sustainability benchmarks such as LEED, BREEAM, or ISO 21930, proving they comply with environmental regulations, labor protections, and carbon reduction mandates.

The largest limitation to the deployment of this technology is not so much technical as cultural, with the construction industry generally reluctant to modernize its practices.

“The construction sector exhibits structural resistance to digital transparency, particularly in procurement and subcontracting practices that rely on legacy workflows, informal relationships, and fragmented documentation systems.”

Most notably, this can impact existing power structures and black or gray market practices endemic in the industry, especially in some countries or regions.

“For many stakeholders, the decentralized and immutable nature of blockchain is perceived not as a facilitator but as a disruptive force that threatens existing operational norms.”

Most likely, deployment of blockchains and other digital tracking tools will happen quickly in critical infrastructure projects, where traceability is not merely a regulatory requirement but a condition for liability management and quality assurance.

AI in Sustainable Construction: Applications and Limits

Applications

As AIs become more versatile, they can now be deployed to improve construction projects.

One application is the integration of AI in environmental impact assessment (EIA) workflows. It allows for accurate prediction from voluminous and heterogeneous datasets, including site-specific environmental indicators, historical project data, and regulatory parameters.

Assistance with legal documents and regulations can have a major impact as well.

“Natural language processing NLP techniques extract structured knowledge from regulatory texts and historical EIA documentation, accelerating compliance assessments and streamlining review cycles.”

Source: Sustainable Futures

Another application of AI is predicting material performances, for criteria as varied as structural integrity, isolation, water resistance, or durability to various stresses (moisture, chloride ingress, freeze-thaw cycles, thermal gradients, etc.).

Limitations

A limit to AI deployment will, however, be the generally low quality of data for input in the industry, reducing the capacity of models and their accuracy.

As more projects become increasingly digitalized, this limitation is expected to fade over time. The same applies to the growing body of data about diverse materials’ performances in real-world conditions over several decades.

Another potential issue is if models are trained on datasets that reflect historical inequities or fail to represent sensitive ecological zones. This can be extra-problematic with AI models whose internal workings can be hard to understand, making it a sort of “black box”.

“The efficiency and analytical depth offered by AI must therefore be balanced against these risks through the implementation of transparent, auditable, and context-sensitive modeling frameworks.”

Synergy Between Eco-Materials, Blockchain, And AI

Swipe to scroll →

| Technology | Main Benefits | Key Limitations |

|---|---|---|

| 3D Printing | Custom design, on-site building, waste reduction | High costs, slow printing speeds |

| Eco-Materials | Lower emissions, recycling of waste, and renewable sources | Cost, scalability, and regulatory acceptance |

| Blockchain | Traceability, smart contracts, ESG compliance | Industry reluctance, cultural resistance |

| AI | Impact prediction, regulatory compliance, material optimization | Data quality, bias, and transparency issues |

Each of these innovations in construction interlocks with the others, making them more useful than if deployed separately.

As more projects integrate blockchain technology for traceability, the amount of high-quality data usable by AI increases.

As digitalization of construction projects increases, it facilitates the integration of CAD and 3D printing technology into actual construction.

Using more eco-friendly materials and implementing better recycling techniques reduces the ecological impact of construction and demolition, thereby increasing the value of high-quality data that can be used to acquire valuable environmental certifications and set new standards for the industry.

Source: Sustainable Futures

Examples of such synergies are already observable in real-world projects. For example, Singapore used many new technologies for the construction of eco-friendly public housing:

- Advanced AI systems to analyze environmental data, such as sunlight exposure, wind patterns, and urban heat island effects, to optimize building orientation and material selection.

- Sustainable materials such as recycled concrete and sustainably harvested wood. These materials are strategically placed within the building’s structure to maximize natural ventilation and light.

- High-performance insulation and windows, as well as solar panels and green roofs, are combined with AI systems that continuously monitor and adjust energy usage based on real-time environmental conditions.

Real-World Examples

The study also presents real-world early adopters of these technologies to demonstrate that we are now firmly in the implementation stage of the technology cycle.

One example is the use of blockchain to solve payment disputes with contractors and suppliers.

“A flagship infrastructure project in Dubai implemented blockchain to streamline contract management and enforce milestone-based disbursements, resulting in measurable improvements in administrative efficiency and reduced financial overheads .”

Blockchain also helped the tracking of materials’ environmental footprint.

“In the Netherlands, blockchain has been trialed to track the real-time quality, delivery, and environmental footprint of core materials such as steel and concrete, ensuring that both material specifications and sustainability thresholds are met without manual inspection bottlenecks.”

A use case of IA was demonstrated in Sweden, where architects and engineers selected advanced insulating materials that optimized energy retention during the winter and minimized heat intake during the summer.

“The implementation of these optimized materials led to a reduction in energy consumption by up to 25 % in newly constructed residential buildings, significantly lowering the carbon footprint associated with these homes.”

AI was also deployed in Japan to automate the recycling of construction waste.

AI-powered sorting systems equipped with advanced imaging and sensor technologies accurately identified and categorized different types of construction waste.

“In a pilot project conducted at a demolition site, the AI system increased the recycling rate by 30 % compared to traditional manual sorting methods.

The efficiency of sorting also reduced the overall time and labor costs associated with waste management, making the recycling process more economical and sustainable.”

Regulatory Challenges in Sustainable Construction

Paradoxically, while most regulations in construction are oriented toward improving safety and environmental profiles, they might also be a hindrance to the deployment of these technologies.

A large part of the potential problems stems from the decline in standardization in construction methods. Custom design might improve the energetic and environmental profile, but they are also hard to fit into the rigid categories and assessment methods mandated by regulations.

One element that can help is the so-called “regulatory sandbox”, allowing for pilot projects to prove their value with less overbearing control.

“These frameworks allow construction firms to pilot digital methods without full regulatory exposure, facilitating innovation while preserving oversight.”

Another improvement can be embedding digital construction requirements within public tendering protocols. This way, governments are not only adapting to, but actively steering the transition toward a digitally-enabled & environmentally-responsible construction sector.

These regulatory changes will need to be managed at the local, national, and international levels.

Source: Sustainable Futures

They also need to move quickly enough to adapt to technological improvements. Otherwise, this could slow down the adoption of innovative technologies like AI and 3D printing in construction, as companies may be reluctant to invest heavily in technologies that might not comply with future regulations.

Future Construction Technologies

Even more impressive materials might one day be integrated into construction projects. For example, nanotechnology in material science offers the potential to create ultra-strong, lightweight construction materials that are both cost-effective and environmentally friendly.

Another option is smart materials that can adapt to environmental changes, such as temperature-responsive polymers that adjust their insulating properties based on weather conditions.

These materials could dramatically increase energy efficiency and comfort in buildings without additional mechanical intervention.

Digital fabrication technologies could also become even more sophisticated, likely incorporating real-time quality control systems, like advanced sensors and AI algorithms to adjust printing parameters on the fly, ensuring optimal material properties and structural integrity.

Robotics could also have a major impact, with, for example, robots performing bricklaying or complex installations of pipes and cables, improving speed and precision while reducing human error and labor costs.

Lastly, AI could have a major impact on research into new materials, from a digital twin of a building observing the evolution of parameters over time to boosting the discovery of new materials, improving material lifespans, and enhancing the understanding of environmental impact throughout a building’s entire life cycle.

Conclusion

Construction has been historically a relatively “low-tech” industry, only integrating new materials slowly and keeping construction methods relatively unchanged.

The simultaneous maturation of CNC, 3D printing, CAD, digital footprint, and AI might change that soon. Especially when combined with a push for lower environmental impact, more traceability, more energy efficiency, and less material consumption.

However, contrary to many other economic sectors, it is unlikely that this will push much human labor out of the construction industry.

Instead, it will improve productivity, safety, and green profiles of new buildings, while enabling better designs and lower resource consumption, all under the supervision of humans still directly handling the messy and changing conditions of a construction site.

3D Printing Company

(Besides the companies discussed below, you can read about others in our article “Top 10 Additive Manufacturing And 3D Printing Stock to Watch”)

Nano Dimension

Nano Dimension Ltd. (NNDM -1.79%)

Most additive manufacturing companies focus on metal and plastic, with an eye for complex mechanical parts. Nano Dimension was instead focused on 3D-printed electronics. This includes very specialized technologies like conductive or dielectric inks & ceramics. These can, for example, be used in the construction of optical or radio components.

This is one of the possible applications of 3D printing to the nanoscale, which we explored further in “Nanoscale 3D Printing Looks Primed for Commercialization”.

Nano Dimension has grown through a mix of acquisitions and internal R&D.

Source: Nano Dimensions

This strategy changed with the acquisition of Desktop Metal, announced in 2024 and finalized in 2025. Together, the 2 companies will have a much stronger position in metal and ceramics 3D printing at all scales, from electronics to large industrial equipment and aerospace, with a strong move into industrial production.

This also creates economies of scale by merging the customer base that includes SpaceX, Tesla, GE, Honeywell, Emerson, Raytheon, NASA, Medtronics, etc.

Lastly, the two companies were mostly active in different geographic areas, with Nano Dimension in Europe and Desktop Metal in the US, allowing for synergy by merging their sales teams.

Source: Nano Dimension

The company claims it can reduce the ecological footprint of manufacturing, with a reduction of 94% in CO2 emissions, 100% in water, 98% in materials, and 82% in chemicals. Overall, we can expect Nano Dimension to emerge as a leader in technology.

Source: Nano Dimensions

The merged companies are well-positioned to leverage new discoveries in 3D printing and develop stronger aluminum alloys, with these innovations likely to expand the addressable market.

However, investors need to be aware that both per-acquisition Nano Dimension and per-acquisition Desktop Metal were cash flow negative, so the resulting company will need to cut costs or grow sufficiently to turn a profit in the future.

(You can read a more in-depth analysis of Nanodimension in the dedicated investment report)