Sustainability

Titanium Nanorods: The Future of Solar Panels

How Titanium’s Light-Reactive Properties Enhance Solar Performance

The reaction of some specific metals or elements to light is already a very important part of the modern world. This is obviously true for silicon in solar panels, but it is also true for many sensors, electronic devices, and many other light-sensitive equipment.

One such metal is titanium. While a lot of the reputation of titanium comes from being a sort of “super steel”, as strong but much lighter and corrosion resistant, this is not actually its main use.

Titanium dioxide (TiO2) consumes 95% of the raw titanium ore mined and is used as a strong white permanent pigment in paints, paper, toothpaste, and plastics. This pigment is resistant to sunlight and chemically inert. It can later be mixed with chemicals to create vivid colors and paints.

The same optical properties are why it is also used in sunscreens, thanks to its ability to reflect and absorb UVs.

Source: Chemours

Another example of titanium’s remarkable optical properties is perovskites, a naturally occurring type of crystal made of calcium and titanium oxide (CaTiO3). Perovskite solar cells, also often called thin-film solar cells, can be installed in combination with silicon or as a stand-alone solar cell.

Source: Department Of Energy

This is why scientists are looking at ways to make titanium react even more with sunlight and other light sources.

Researchers at the University of Science and Technology of China and the Chinese Academy of Sciences have discovered a new way to grow titanium dioxide nanorod arrays (TiO₂-NA) and demonstrated their application in high-performance solar cells.

They published their results in the scientific journal Small Methods1, under the title “Unveiling Growth and Photovoltaic Principles in Density-Controllable TiO2 Nanorod Arrays for Efficient Solar Cells”.

Metal Nanorods

When it comes to chemical or optical reactions, the actual surface of a metallic surface is important. If it is smooth, it will be roughly the size of the material as seen with your eyes.

But if it has more complex microstructures, it can have dozens or hundreds of times more contact surface, boosting the efficiency and speed of the desired reaction.

For example, this is how researchers are using nickel nanorods to catalyze hydrogen production without precious metals like platinum.

The same method can be used to create titanium nanorods, measuring barely a few nanometers in diameter.

Source: ResearchGate

It is known that single-crystalline TiO₂ nanorods excel at harvesting light and conducting charge, making them ideal for solar cells, photocatalysts, and sensors.

However, traditional fabrication methods struggle to control all the parameters at the same time, like rod density, diameter, and length. At least until now.

How Controlled Nanorod Growth Is Achieved

The researchers improved a stage where the film is subjected to hydrothermal treatment, where the nanoparticles are converted in situ into rutile (a form of titanium dioxide).

Source: ResearchGate

They are serving as seeds for later nanorod growth. This method provides an effective way to control the rod density without altering the nanorod dimensions.

Source: ResearchGate

This way, the researchers managed for the first time to produce constant rod diameter and height, even while the number of rods per area varied.

Source: ResearchGate

Titanium Nanorods in Next-Gen Solar Cell Efficiency

These nanorods were incorporated into low-temperature-processed CuInS₂ solar cells (copper-indium-sulfide). This type of solar panel, still in development, could be a possible, non-toxic alternative to cadmium-based semiconductors.

Source: ResearchGate

The titanium nanorods improved the solar cell’s light trapping, charge separation, and carrier collection.

The solar cell reached the 10.44% power conversion efficiency, a new record for this type of solar cell.

This is not to say that CuInS₂ solar cells are yet ready for commercial applications, as more common silicon cells or, even perovskite and cadmium-telluride thin film cells, all with efficiency superior to 20%.

The design is, however, promising, as it could be mass manufactured (synthesized and processed using solution-based methods) and it could theoretically be as efficient as silicon cells.

This type of material could also be integrated into other solar cell designs, as the primary light-absorbing layer in a more complex design incorporating other elements.

Comparing Solar Cell Technologies

To better understand where CuInS₂ + TiO₂ nanorod solar cells stand, here’s how they compare with other prominent types:

| Solar Cell Type | Primary Material | Power Efficiency | Toxicity | Commercial Readiness |

|---|---|---|---|---|

| Silicon | Crystalline Silicon | ~20–25% | Non-toxic | Commercial |

| Perovskite | Calcium/Titanium Oxides | >20% (lab) | Low to Moderate | Pre-commercial |

| CuInS₂ + TiO₂ Nanorods | Copper-Indium-Sulfide + Titanium Dioxide | 10.44% (record) | Non-toxic | Experimental |

| CdTe (First Solar) | Cadmium Telluride | 18–22% | Moderate (Recyclable) | Commercial |

Investing in Solar

First Solar, Inc.

First Solar, Inc. (FSLR +3.15%)

First Solar is the largest solar panel manufacturer in the USA and in the whole Western hemisphere, with manufacturing sites in the US, Malaysia, and Vietnam.

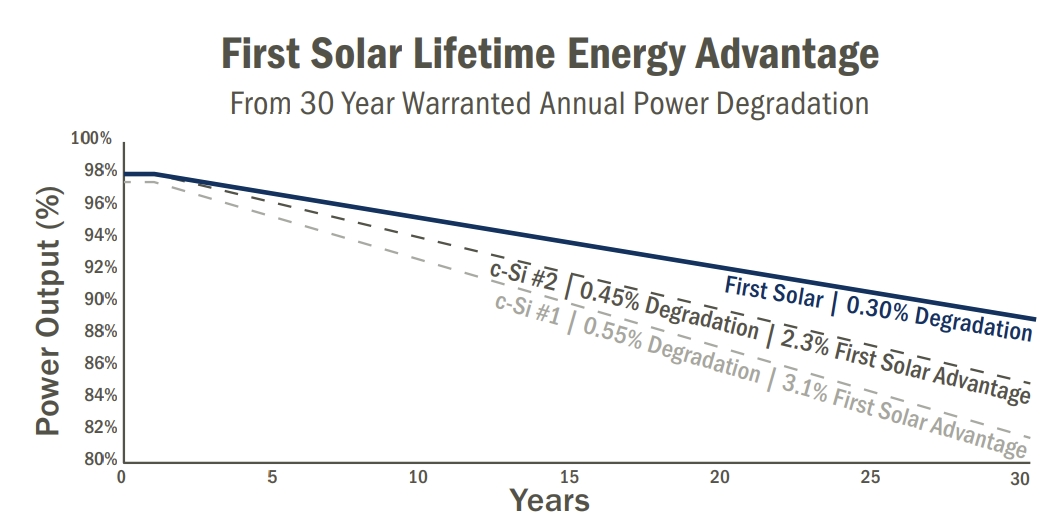

The company is not using the classic crystalline silicon technology and instead uses its proprietary thin-film photovoltaics. Based on cadmium-telluride, they are more efficient, are produced at a lower cost, and can easily be mass-manufactured. Thin-film solar panels are also more durable, retaining 89% of their original performance after 30 years.

Source: First Solar

Cadmium and telluride are byproducts of the mining for other metals, which means that First Solar products have a minimal impact, using resources that were of little use before. Thin-film panels can also have a high recycling rate.

First Solar’s technological edge, combined with its geographical location, makes it the likely beneficiary of the growing push for Western countries to source their panels from outside of China.

The company is ramping up its production capacity quickly, aiming to reach a nameplate capacity of 25 GW by 2026, from the current 11 GW.

While focused on producing the more mature cadmium telluride solar panels today, First Solar is exploring other thin-film technologies as they become ready for commercial-scale production.

It notably commented in its investor presentation that perovskite should have a “development line readied for producing technology samples of perovskite, simulating manufacturing-like condition”.

First Solar has spent a cumulative $2B in R&D since its inception.

Overall, First Solar is a technology leader that stands to benefit from tariffs on Chinese imports, something likely to compensate for the negative effect on the solar industry from Trump’s reelection.

While mostly focused on thin film solar using cadmium telluride so far, its expertise in non-silicon solar panel manufacturing could give it a significant head start with perovskite or other titanium-based solar panels, especially considering its deep ties to some of the top researchers in this field.

Latest First Solar (FSLR) Stock News and Developments

What Drives First Solar's Long-Term Solar Module Competitiveness?

First Solar (FSLR) Falls More Steeply Than Broader Market: What Investors Need to Know

Why Investors Need to Take Advantage of These 2 Oils and Energy Stocks Now

First Solar (FSLR) Stock Declines While Market Improves: Some Information for Investors

First Solar, Inc. (FSLR) Is a Trending Stock: Facts to Know Before Betting on It

FSLR Stock Down 13.8% in Three Months: What's Next for Investors?

Study Referenced

1. Wenbo Cao, Chao Dong, Chaofan Zheng, Jiajin Kuang, Yang Wang, Faisal Naveed, Mengqi Jin, Yingying Dong, Chong Chen, Mingtai Wang. Unveiling Growth and Photovoltaic Principles in Density-Controllable TiO2 Nanorod Arrays for Efficient Solar Cells. Small Methods. 22 April 2025. https://doi.org/10.1002/smtd.202500264