Additive Manufacturing

Quick Drying 3D Printed Clay-Hemp Polymer To Replace Concrete

Securities.io maintains rigorous editorial standards and may receive compensation from reviewed links. We are not a registered investment adviser and this is not investment advice. Please view our affiliate disclosure.

Concrete’s Environmental Limits: Sand Use and CO₂ Emissions

Concrete has become the central material in construction over the past few decades, especially in dense urban environments. It has progressively replaced bricks, stone, and wood, thanks to its low cost, ease of use, and scalability.

But it is not without issues.

First, it is far from a sustainable product when it comes to resource consumption. It uses tremendous amounts of sand, to the point that reports suggest the world is “running out of sand.”

Source: Visual Capitalist

The production of cement is also a very energy-intensive activity. It is almost exclusively powered by fossil fuels, resulting in cement production being responsible for 8% of the world’s CO₂ emissions.

This is comparable to the emissions from cars and vans, which are responsible for 10% of global emissions. Consequently, making concrete more sustainable would be as impactful as transitioning all of the world’s cars to EVs and powering them only with green energy.

How Clay-Hemp 3D Printing Creates a Low-Carbon Concrete Alternative

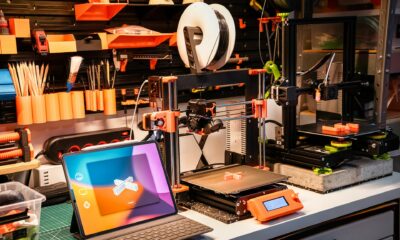

Parallel to the search for greener alternatives to traditional concrete, the idea emerged of using 3D printing principles to build houses.

Instead of labor-intensive methods like bricklaying, an automated 3D printing machine can assemble walls quickly.

However, printing the walls does not eliminate the long curing time required for concrete; there is still a 28-day waiting period before the structure achieves full strength.

Researchers at Oregon State University have now developed a concrete substitute that is significantly less carbon-intensive while remaining compatible with 3D printing technology.

They published their results in Advanced Composites and Hybrid Materials1 under the title “3D printing of sustainable infrastructure using rapid-set clay concrete with biobased additives.”

Swipe to scroll →

| Property | Traditional Cement Concrete | Clay–Hemp Polymer Concrete (OSU) | Low-Carbon Electrolyzer Cement (Sublime) |

|---|---|---|---|

| Binder | Portland cement, kiln-fired clinker | Acrylamide-based polymer binder using RICFP | Electrolyzer-based cement made at ambient temperatures |

| Bio-based / in-situ content | Low; mainly quarried aggregates | ≈75% clay, sand, hemp fibers, biochar by weight | Depends on local calcium sources (industrial by-products, rocks) |

| Strength immediately after placement | Effectively 0 MPa; requires formwork | ≈3 MPa right after 3D printing | Early-strength profile still being scaled and tested |

| Days to reach 17–24 MPa structural strength | Typically up to 28 days | ≈3 days to surpass 17 MPa | Targeting similar or better, varies by mix and plant |

| Full curing time | ≈28 days | ≈8–14 days (over 40 MPa) | Plant-specific; designed to avoid kiln process |

| CO₂ footprint vs ordinary Portland cement | High (kilns and process emissions) | Lower, thanks to bio-based aggregates and no cement kiln | Designed to be substantially lower by avoiding limestone calcination |

| 3D printing capability | Requires supports, slower curing, limited overhangs | Can print free-standing overhangs and gaps without supports | Early-stage; focus on batch production of low-carbon cement |

Inside the Clay-Hemp Polymer: RICFP and Bio-Based Aggregates

Cement is typically comprised of calcium, silicon, aluminum, and iron, which are ultimately heated in a kiln and ground into a fine powder.

Instead, the researchers developed a 3D-printable, clay-based construction material using a method known as Radical-Induced Cationic Frontal Polymerization (RICFP).

It relies on three key chemical components:

- A monomer that polymerizes in the presence of a free radical.

- A crosslinker that links polymer strands together.

- An initiator that, under high temperature, releases the free radicals needed to start the polymerization.

The researchers achieved this by combining the RICFP binder with clay aggregate, sand, biochar, and hemp fiber to improve compressive strength, insulation, and sustainability. To this, a binder was added, made of acrylamide (ACR) monomer, methylenebisacrylamide (MBA) cross-linker, and ammonium persulfate (APS).

In total, this managed to use 70–80% bio-based materials by weight.

Superior Strength and Faster Curing Than Traditional Concrete

The main improvement this material provides compared to concrete is higher strength, especially immediately after 3D printing.

With a buildable strength of 3 megapascals (MPa), it enables the construction of multilayer walls and freestanding overhangs like roofs.

This strength increases over time, creating a very solid final building.

“It surpasses 17 megapascals, the strength required of residential structural concrete, in just three days, compared to as long as 28 days for traditional cement-based concrete.”

Devin Roach – Assistant Professor of Mechanical Engineering, OSU College of Engineering

Another advantage is cure time: the material reaches the 17 MPa strength required for residential structural concrete in just three days. It fully cures in under two weeks—compared with around 28 days for traditional cement-based concrete.

The researchers also tested different 3D printing construction methods. They demonstrated that higher strength and rapid polymerization enable the new mix to be printed without an underlying structure.

This new method could also be used to print normally shaped doors and windows, features that usually require extra materials or special methods with concrete 3D printing.

“The material’s ability to print free standing structure without the use of supports, including various and unique capabilities of printing with frontally polymerizing concrete.”

What Clay-Hemp 3D Printing Could Mean for Future Buildings

While 3D-printed houses and construction materials initially used concrete, it is likely that this novel construction method will benefit from new materials.

For now, as it is still at an experimental stage, the clay-hemp-biochar-based material is more expensive than concrete.

But further refinement and reduction in construction costs, thanks to 3D printing efficiencies, should ultimately bring it on par with traditional materials.

In addition, the superior carbon footprint could be a decisive factor if carbon taxes begin to impact cement costs heavily.

Investing in Cement Production

Investor Takeaway – Clay-Hemp 3D Printing & CRH

Clay-hemp polymer concrete is still in the lab and pilot stage, but it sits in the slipstream of three powerful forces: construction decarbonization, automated 3D-printed building, and fast-curing materials that compress project timelines. The Oregon State University mix shows how bio-based aggregates and polymer chemistry can deliver structural strength in days instead of weeks, with a much lower CO₂ footprint than traditional cement. For public-market investors, CRH is one of the clearest ways to get exposure to this transition. The company is the largest recycler in North America, has already begun cutting cement emissions with alternative fuels, and is deploying capital into low-carbon cement innovators like Sublime Systems, carbon-capture technologies, and AI-driven mix optimization. If electrolyzer-based cement and advanced 3D-printed mixes scale commercially, incumbents with global distribution, capital, and regulatory relationships—like CRH—are best positioned to own the transition rather than be disrupted by it.

CRH: A Sustainable Cement Leader and Decarbonization Play

CRH plc (CRH +2.08%)

As one of the world’s leaders in cement production, CRH will be instrumental in turning cement construction into a more sustainable industry. It ranks #1 in total volume of construction material provided in both the US and European markets.

The company is active in 28 countries and 3,390 locations, employing 78,500 people, with CRH Americas making 65% of its 2023 global sales.

CRH expects robust spending by Western governments on infrastructure to help grow its business. The trends of re-industrialization and on-shoring high-tech manufacturing should also help.

Source: CRH

CRH has made serious progress in sustainability with a series of initiatives:

- It is the largest recycler in North America, with 43.9 million tons of waste and by-products from other industries recycled in 2023.

- It reduced its CO₂ emissions by 8% in 2023, thanks to using 36% alternative fuels in its cement plants.

- It is aiming for a reduction of emissions by 30% by 2030 (compared to 2021 emissions).

This is laudable in itself, but it can be seen as too little, too late, considering the carbon emissions of the concrete industry.

Luckily, CRH is also a driver of more fundamental changes to the sector. Notably, it has invested $75M into low-carbon cement company Sublime, together with the European concrete giant Holcim.

Sublime Systems was spun out of MIT in 2020 to utilize an electrolyzer to produce cement at ambient temperatures, replacing energy and fossil fuel-intensive kilns. It also enables the use of calcium sources as an input material, avoiding the release of CO₂ from limestone input.

Sublime’s first commercial facility in Holyoke is expected to open as early as 2026. If proven successful, it could be the real game-changer for the cement industry, and it could open the way to scalable low-emission concrete.

CRH also invested in other decarbonization and sustainability startups:

- €23.7 million in Cool Planet Technologies, developing carbon capture solutions for industries that have traditionally been difficult to decarbonize.

- $34.7M by CRH and other investors in Carbon Upcycling Technologies, using an all-electric mineralization solution to permanently store CO₂ in industrial by-products and minerals, like cement, plastics, consumer products, fertilizers, and pharmaceuticals.

- AICrete, a ‘recipe-as-a-service’ platform that works with local concrete producers, optimizing local materials and minimizing the amount of cement used using AI analyses, reducing both the CO₂ footprint and the cost of concrete production.

- FIDO AI’s Series B funding is a startup using AI to reduce water consumption and increase water savings.

Lastly, CRH is also investing in 3D concrete printing (3DCP) through its subsidiary Amerimix.

Overall, CRH is a profitable leader in the concrete and construction industry and is very actively preparing for the decarbonization of the industry, both directly in existing facilities and by being a prime provider of capital to innovative startups creating the next generation of cement and concrete production technology, including decarbonization and 3D printing.

Latest CRH (CRH) Stock News and Developments

Wall Street Bulls Look Optimistic About CRH (CRH): Should You Buy?

What Analyst Projections for Key Metrics Reveal About CRH (CRH) Q4 Earnings

Crh Plc $CRH Shares Sold by Caisse Des Depots ET Consignations

CRH (CRH) Advances While Market Declines: Some Information for Investors

Azzad Asset Management Inc. ADV Buys 7,257 Shares of Crh Plc $CRH

Simpson Manufacturing (NYSE:SSD) vs. CRH (NYSE:CRH) Financial Contrast

Study Referenced

1. Nicolas A. Gonsalves et al,. 3D printing of sustainable infrastructure using rapid-set clay concrete with biobased additives. Advanced Composites and Hybrid Materials. Volume 8. 01 October 2025. https://link.springer.com/article/10.1007/s42114-025-01456-1