Energy

The Future Of Energy Storage – Utility-Scale Batteries Tech

The Power Grid Need For Batteries

Batteries have evolved from a cheap component of small electronics to an expensive key component in the EV revolution. But there is another segment besides mobility that requires an increasingly large amount of battery capacity: the power grid.

Renewables are growing as a part of total electric power generation. But they are also more intermittent than fossil fuel-based power plants, as they mostly produce power when the sun shines or the wind blows. This might not coincide with the time of peak consumption, often in the evening or winter. The power grid does not store any electricity but needs to be balanced between production and consumption at all times.

So the more renewables generation, the more batteries will be needed to keep your power grid stable. This is a major area of new energy investment, with utility-scale battery projects scheduled to more than triple the current capacity by 2025.

Source: EIA

For now, a lot of these batteries parks are using lithium-ion batteries. But this might change.

Different Needs

For now, the battery industry has evolved mostly to cater to the small electronics and EV market. This is because both share similar requirements for the ideal battery:

- Small and lightweight, so with high density as measured in Wh/kg.

- Operate in a “normal” temperature range.

- Not extremely price-sensitive.

- Can last at least 5-10 years, with approximately a full charge per day.

For this specific set of criteria, lithium-ion technology has so far been the best for battery technology. This might change soon, with possibilities like solid-state batteries, sodium-ion, or lithium-ferrum-phosphate (LFP) batteries as potential alternatives. You can read more about it in our article: “The Future of Mobility – Battery Tech”.

But power grid / utility-scale batteries have very different needs.

- No hard constraints on weight. Batteries are not moving anywhere so a weight that would cripple an EV is not a problem.

- No hard constraints on space. Battery parks will be built on cheap land around power stations. No need to pack it tight inside the frame of a computer or an EV.

- High temperatures are not so problematic. If a specific chemistry works better at 200C, this will not cook the passengers of an EV. However, in most countries, the batteries will need to tolerate cold weather, as having to keep them warm in winter would be very costly. Something lithium-based batteries can struggle with.

- The cost of each Wh is the most important factor.

- The longer the battery lasts, the more its cost can be amortized over a long period of time, with utility companies used to invest with a 30-40 years timeframe.

Considering the very different needs between EVs and utility-scale batteries, it is no surprise that new technologies and new battery chemistries are being developed to provide more cost-effective solutions to power companies and grid operators.

In practice, we can expect several different energy storage technologies to “win” together, as some are more fit for immediate grid balancing, and some more for different time scales (hours, weeks, entire seasons).

Source: CleanTech

While this article will give you an overview of the topic, you might also want to read this detailed report from Ara Ake on stationary energy storage systems.

New Battery Chemistries For Grid-Scale Applications

EVs-Derived New Chemistries

Building batteries is a scaling game. The largest production batches, with the deepest supply chain, can manage economies of scale and therefore a cheaper cost per Wh.

For this reason, quite a few utility-scale battery companies are betting on low-cost battery chemistries already used in EVs to replace lithium-ion-based storage.

LFP Batteries

One option is LFP (lithium-iron-phosphate), a good candidate for low-cost EV batteries, and a battery chemistry not relying on expensive cobalt and nickel. They are also longer lasting than lithium-ion, making them even more economical in the long run. This is something already available in ready-made, utility-scale solutions, including from leaders in the sector like CATL or BYD.

Sodium-Ion Batteries

Besides cobalt and nickel, lithium itself can be very expensive at times, depending on the fluctuation of the lithium price. So replacing it with abundant sodium can help reduce prices even more. It is slightly less energy dense (Wh/kg) than LFPs, but also cheaper, so might be an even better candidate for a battery chemistry able to work both in EVs and the power grid.

Redox Flow Batteries

These categories of batteries rely on the chemical process of oxidation and reduction of metal. A variety of different metals can be used for redox-flow batteries, as well as other types of ion flows.

Source: CellCube

Iron-Air Batteries

These batteries work by utilizing the oxidation of iron (commonly known as rust). The batteries produce electricity by oxidizing iron, and then reverse the process by consuming electricity.

The key advantage is that by utilizing extremely cheap materials, these batteries could be extremely cost-effective. Advocates for this technology are claiming iron-air batteries would be 10 times cheaper, perform better, and last 17 times longer. The downside of the batteries being big, heavy, and slow to charge or discharge should not really be an issue for utility-scale applications. Companies like Form Energy are already building facilities to mass manufacture these batteries.

Zinc Batteries

Using another cheap metal, these batteries include several options like zinc-bromine, zinc-manganese, or zinc-air chemistries. The key advantage of this technology is its very long storage capacity, with very little losses/discharge. This could make it a good candidate for storing wind power, with windless days sometimes stretching for several weeks, something battery technologies with less durable storage can struggle to compensate for. “Zinc batteries are expected to comprise 10% of the storage market by 2030, according to energy analyst Avicenne Consulting”. Some notable companies in this space are Redflow (zinc-bromine) and Zinc8 (zinc-air).

Vanadium Redox Flow Batteries – VRFB

Vanadium is a metal mostly used today in the production of stainless steel. In batteries, it could create batteries that are best fit for daily cycles and smoothing the production curve of renewables during the day, thanks to being able to handle at least 10 charge-discharge cycles per day, while also having a good retention capacity for up to 24 hours. The battery lifespan can be very long, up to 20-25 years, and even then it would just need replacement of the plastic frame parts, with the metal components almost fully recyclable.

The sector is very active, with companies like CellCube, Invinty Energy Systems, Rongke Power, and VRB Energy working on this technology.

Sea-Salt / Aqueous Saltwater Batteries

This concept relies on the flow of salt ions through a membrane for storing energy. Some version of this battery made by Salgenx does not even use a membrane at all, which reduces costs, complexity, and maintenance, but with a custom-made electrolyte that does not mix with water.

Molten Metal Batteries

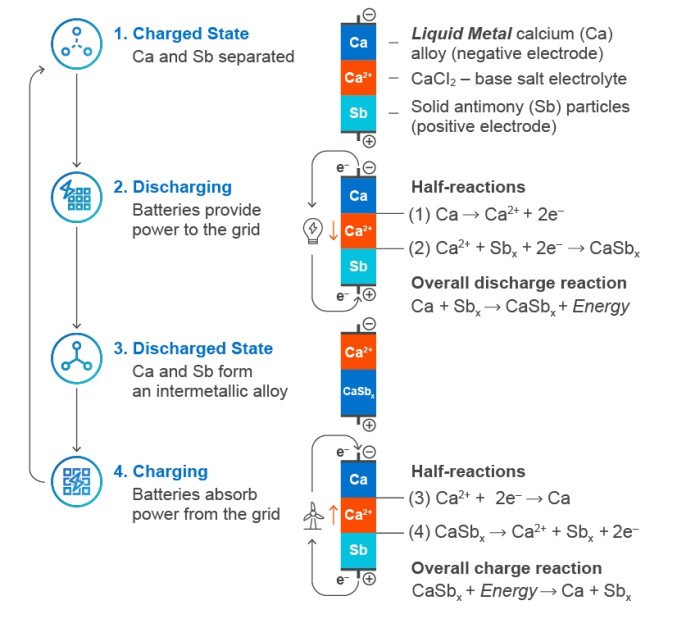

The concept is based on aluminum smelting, a very electricity-hungry process; what if it could be reversed?

A lot of battery costs come from the difficulties of manufacturing them. Anodes and Cathodes need to be perfectly separated to avoid shortcuts.

In a molten metal battery, all 3 main components, the anode, cathode, and electrolyte are liquid. They separate spontaneously from each other thanks to different liquid densities. The fact that there are no solid components should in theory increase the battery’s lifespan dramatically, as well as allow it to charge and discharge very quickly and to be fully recyclable.

The company Ambri, using a calcium and antimony battery, is aiming for producing 200,000 battery cells per year in its new factory by 2024, and has been a supplier to Microsoft since 2022.

Source: Ambri

The company NGK insulator is also working on a sodium-sulfur molten salt battery, and the company FZSoNick is working on a sodium-nickel-chloride battery.

Metal Hydrogen / Nickel Hydrogen Batteries

These batteries cycle hydrogen into water and then oxidize a metal. While nickel is not the only possible cathode metal in this technology (alternatives can be manganese, lead, or iron), it is the most common and energy-dense option.

This is the type of battery used by NASA on the ISS (International Space Station).

This technology would have the advantage of being very safe, with zero maintenance and managing a wide range of temperatures (-40 to +60C).

This technology is notably promoted by Enervenue, which came out of stealth mode in 2020, showing a new version of its battery with a 30-year, 30,000-cycle lifespan released in September 2023. Hydrogen-manganese batteries are developed by RFC Power.

CO2 Batteries

Rising CO2 levels are the driving force behind the push for renewables and electrification, and therefore behind the increasing need for batteries as well. So it would be somewhat ironic that the same molecule becomes used to store renewables energy.

Noon Energy CO2 battery splits CO2 into carbon and oxygen to store energy. The flow battery is operated at high pressures and temperatures ranging from 50 to 200 bar and 600 to 800 ºC. This battery type was first developed for the Mars Rover Perseverance.

This should not be misunderstood to be the same as the “CO2 battery” from Energy Dome, which relies on the cycle of liquefaction and evaporation of CO2, making it not a true battery, but more akin to a compressed gas energy storage.

Sodium-Sulfur Batteries

These batteries had, for now, been limited to applications where the battery was kept at high temperatures (300°C). This might not be an issue for utility-scale applications. However, the technology is still somewhat new and lacks scale and mass production for now. Making these batteries very long-lasting can also be a technological challenge.

Polymer Batteries

Also called plastic batteries, this concept uses conductive polymer instead of lithium or other metals. The main advantage of this concept is that it relies on simple manufacturing and materials readily available. The resulting battery would also be very long-lasting and easy to operate safely.

Polyjoule, an MIT spin-off, is one of the leaders in that idea. But it might in the long run not be a battery type that can reduce costs as much as some other alternatives.