Electronics

Silicon Carbide: Fueling the Green Energy Revolution

Securities.io maintains rigorous editorial standards and may receive compensation from reviewed links. We are not a registered investment adviser and this is not investment advice. Please view our affiliate disclosure.

The Rise of Silicon Carbide in the Silicon Age

In the far distant future, historians might refer to our era as the Silicon Age. At first glance, this seems to be thanks to the omnipresent silicon chips in our computers, smartphones, appliances, and maybe soon even our brains.

But this is not the only use of silicon, an abundant material that is found in ordinary sand. Polysilicon is the basic component of most solar panels, which are bringing us closer to a solar-powered economy.

A new type of silicon-based material is becoming equally important, but often less known by investors and the broader public: silicon carbide.

This association of silicon and carbon is superior to silicon alone in some key characteristics:

- A 10x higher electric field capacity, making it able to handle very large power loads.

- As a result, silicon carbide devices can be smaller and switch on and off more quickly.

- 3x the thermal conductivity of “normal” silicon, allowing for much quicker heat dissipation when exposed to high charges.

- Much smaller losses result in more efficiency and even less unwanted heat production.

Due to these properties, silicon carbide has become essential in any application dealing with high-power use and electronics: solar inverters, EVs, industrial power supply, etc.

Silicon Carbide 101

Silicon carbide, also known as carborundum, or SiC, can be found naturally in meteorites, but almost nowhere else on Earth naturally.

Source: Global IMI

The material comes in many different crystal shapes, up to 200 different structures, each having slightly different chemical and physical characteristics.

Source: MRF

When it comes to electric and thermal conductivity, silicon carbide vastly outperforms silicon in almost all possible metrics.

Source: MRF

Silicon Carbide Production

The bulk production of silicon carbide is relatively simple and was first patented in 1893, utilizing a method known as the electric batch furnace. The process heats together a mix of silica (sand) and carbon (coking coal) to very high temperatures, typically 1,600°C-2,500°C (2,900°F-4,500°F).

Nitrogen and aluminum are common impurities from this manufacturing process, but they affect the electrical conductivity of SiC.

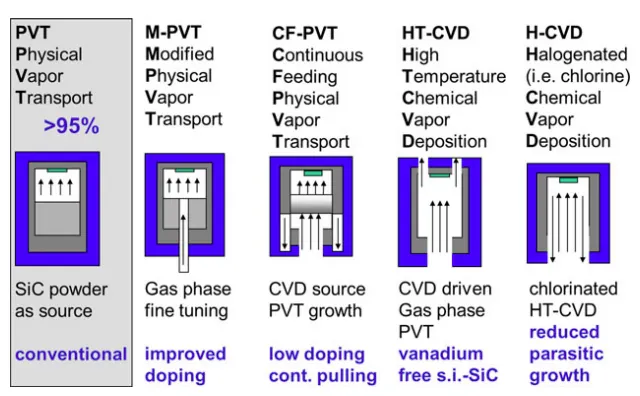

Alternative methods, mostly used in producing electronic components requiring higher purity levels, are physical vapor transport (PVT), chemical vapor deposition (CVD), or Liquid Phase Epitaxy (LPE).

These methods differ in how the silicon carbide is delivered, but all share the idea of producing an initial crystal and then growing it. The large crystal is then cut into extremely thin slices into silicon carbide wafers, similarly to how silicon wafers are made for electronic production.

Source: MRF

Overall, the silicon carbide manufacturing process and supply chain are very similar to the silicon manufacturing industry, with similar CVD, wafers, etc.

Because of the 200+ crystal forms the material can take, the production process needs to be tested and an exact calculation done for large-scale production. The information for these processes is usually proprietary to the individual companies, so R&D is needed during the beginning stages of the creation of a specific process for making silicon carbide.

Half of global silicon carbide production is located in China, and production capacity is expected to almost quadruple between the 2023 level and 2027.

Source: McKinsey

Silicon Carbide Markets

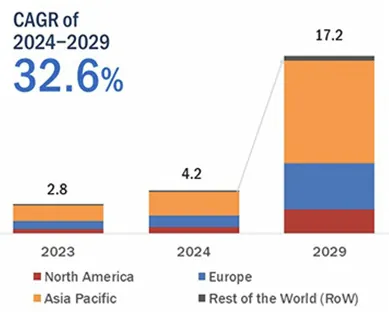

Silicon carbide is still a small market in 2024, worth only $4.2B. It is, however, expected to grow extremely quickly at 34.5% CAGR, bringing it to $80.2B by 2034.

Source: Markets & Markets

Power applications (SiC modules) are where most of the growth is expected to come from, driving the overall demand for silicon carbide higher.

The market can be divided between black silicon carbide (with metal impurities) and green silicon carbide (high-purity SiC).

Black silicon carbide is mostly produced for cheap abrasive, while green silicon carbide or direct production of crystal (“other types”) is the raw material used for high-tech applications.

Source: Global Market Insights

In the power application, EVs and other green vehicles (hybrids, fuel cells, etc.) are expected to be the main driver for higher demand for silicon carbide.

Source: McKinsey

| Sector | Use of SiC | Benefit |

|---|---|---|

| Electric Vehicles | Inverters, chargers, power control | Higher efficiency, range, fast charging |

| Solar Energy | SiC-based inverters | Increased efficiency, smaller footprint |

| Aerospace | Heat shields, mirrors | Thermal resistance, low expansion |

| Robotics & Data Centers | Power electronics, motor drives | Lower power loss, miniaturization |

| Defense & Safety | Armor plates, braking systems | Hardness, heat and impact resistance |

Silicon Carbide Applications

Silicon Carbide in Electric Vehicles

By far the most important application for silicon carbide in the coming decade, power electronics is where this material is the most irreplaceable.

The largest sub-section of this category is electric vehicles, expected to grow by 31% per year. SiC is not only present in the power electronics and controllers, but also in the battery, monitoring system, and chargers, both in the car and the charging station.

Source: EV Mechanica

Already in 2023, it was demonstrated that a silicon carbide inverter can increase the range of an EV by 7%. Since then, a lot of newer EV designs have started to incorporate more SiC components.

The demand growth from the EV segment might be even underestimated in the case of a switch to electric for heavy-duty vehicles like trucks, which will require a much more powerful charging system and enough battery packs to power dozens of EVs.

Silicon carbide is also key for so-called “superchargers”, a key to solving a resistance point in EV adoption, with the goal of reducing charging time to mere minutes.

The lower thermal stress and more consistent power supply should also help the batteries’ longevity.

Silicon Carbide’s Role in Green Energy and Solar

SiC-based inverters for solar power can reach up to 99% efficiency, compared to traditional silicon-based inverters at only 96-98% efficiency. While seemingly small, this can result in a large amount of extra energy over the lifetime of a solar installation.

Silicon carbide is also a lot more heat resistant, able to endure temperatures of up to 300° Celsius, while silicon devices are generally limited to 150°C, and 10x the voltage.

Overall, SiC inverters are more efficient, more durable, smaller, and cheaper than older, silicon-based inverters.

Other High-Tech Uses for Silicon Carbide

Silicon carbide is also increasingly used in many applications like robotics, where SiC’s superior performance allows for the motor drive to be smaller and located directly in the articulations, greatly reducing complexity and cabling required.

Source: Arrow

They are also growing in importance in data centers, where increasingly powerful chips and power demand from AI require stronger power supply and control electronics than silicon can provide.

A silicon carbide crystal was used in the creation of the first LED in 1907. It was then mass-manufactured in both Western countries and the Soviet Union in the 1970s and 1980s. It would later be replaced by gallium nitride, with 10-100x brighter light, leading to today’s mass adoption of LEDs.

SiC is, however, still used in LEDs, as the substrate on which gallium nitride is deposited, and to disperse heat in powerful LEDs.

Abrasives

SiC is a very hard material, making it useful as an abrasive in grinding wheels, sandpaper, and other abrasive products for grinding materials like metals and ceramics. It is usually the lower grade, cheaper, and impurity-rich black SiC that is used for these applications.

Higher grades of SiC are used in cutting tools, also making use of the extremely high hardness of this material, but with the higher purity making it even stronger and less brittle.

Protective Materials

The combination of high hardness and thermal resistance also makes SiC important in other applications. It is generally sintered (partial melting) into hard ceramics.

One application is in the production of ceramic bulletproof armor plating, especially plates in personal body armor, where SiC controls 27% of the market, but also in helicopter armor.

These hardened ceramics are also used in car brakes and car clutches.

Silicon carbide ceramics are also used in aerospace applications, for example, in the outer thermal protection layer of NASA’s LOFTID inflatable heat shield.

Another space-focused application of SiC is in the production of astronomical telescopes, with chemical vapor deposition allowing for a large disk of SIC used as mirrors in the telescopes. The low heat expansion can also be used as a frame for the very precise machinery of the telescopes.

Chemical Catalysis

The high reactivity of silicon carbide to electricity makes it a potential candidate for new forms of electrocatalysis. These reactions usually rely on a form of silicon carbide crystals called cubic silicon carbide, with a larger surface area.

For example, it has recently been discovered to be a good candidate for improved photocatalysis of hydrogen, or the direct breaking of water into hydrogen by sunlight.

Cubic silicon carbide can also be used as a catalyst support for the oxidation of hydrocarbons.

Lastly, silicon carbide could be used to grow graphene semiconductors.

Nuclear Energy

Silicon Carbide has a very strong capacity to absorb neutrons, so it is used as cladding for nuclear fuel, as well as to contain nuclear waste.

SiC sensors are used to monitor radiation levels in nuclear facilities and other radiation detection applications (environment, medical setting, etc.).

SiC’s resistance to radiation and thermal variation makes it a good material for space-bound nuclear reactors, a growing field with NASA and other nations’ plans for the Moon and even maybe Martian bases.

Jewelry

A crystal based on carbon, SiC shares many characteristics with diamond (pure carbon), and is known as “synthetic moissanite” in jewelry. It can easily be misidentified as diamonds.

Source: MRF

Mitigating Rare-Earth Risks with SiC

As trade wars, tariffs, and sanctions disrupt the USA-China trade relations, the automotive industry is facing the very serious issue of potentially running out of China-made rare earth materials, with, for example, Ford shutting down a factory.

“It’s day to day. We have had to shut down factories. It’s hand-to-mouth right now.”

Jim Farley – Ford CEO

This is a field where Sic can help, thanks to silicon carbide allowing for separately excited synchronous motors, removing the need for permanent magnets requiring rare earth.

So while on the one hand, silicon carbide businesses could suffer if the EV supply chain was severely disrupted, on the other hand, their product could be more widely adopted in new EV designs in the future, in order to reduce the reliance and dependencies on Chinese rare earth supplies.

Conclusion

Silicon carbide is not a new material, but mass production of ultra-pure and small electronics made from it, with vastly superior electrical properties, is.

It has opened the door to many new applications, currently being widely adopted to replace older silicon-based options in a wide array of quickly growing industries, especially EV & solar energy.

The more the world industry and transportation electrifies, the more silicon carbide it will need, as more intense power demand requires stronger chargers, batteries, and controllers to help quick and safe charging, more durable batteries, etc.

Besides these applications, the mass production of SiC and the improvement of production methods are likely to decrease its production costs. As a result, other applications like armor, heat shield, aerospace, and tooling are likely to start adopting SiC more often.

Lastly, new potential fields of applications are still opening, notably the possibility of using silicon carbide for the production of green hydrogen.

Overall, silicon carbide is likely to become a much more well-known material by the broader public in the future. With an expected CAGR in the 20-30% range for the decade to come, investors might want to pay attention to this small but quickly growing sub-section of the semiconductor industry.

Silicon Carbide Companies

ON Semi

ON Semiconductor Corporation (ON +2.1%)

ON Semi is a semiconductor company specializing in electrification, including in automotive, but also in other sectors like solar energy, batteries, aerospace, telecommunication, data centers, and medical.

As such, it is a key partner for many of the largest industrial companies in the world.

Source: ON Semi

A big part of ON Semi’s technological advantage is based on silicon carbide, especially in the case of very high power loads required for the fast charging of EVs.

ON Semi’s strategy of doubling down on silicon carbide led to the company experiencing a massive surge in revenues in the last few years, carried by the EV revolution.

Source: ON Semi

Silicon carbide sensors are both more energy efficient and perform better in low-light settings, which will be crucial for building safe self-driving cars.

ON Semi’s silicon carbide products are also used in all sizes of solar energy installations, data centers, and sensors of all kinds (ultrasonic, electrochemical, like blood sugar monitoring, and metallic object detection).

Riding the trend of electrification, ON Semi controls 10% of global SiC revenues, and is one of the leading North American companies in the sector, competing with European companies Infineon (IFNNY) and broader semiconductor company STMicroelectronics (STM +0.46%).

Source: McKinsey

As the Western industrial supply chains are relocalizing away from Chinese supply, ON Semi will likely greatly benefit from the electrification trend, especially in EVs and other green energies.

(You can also read a longer write-up about this company in “On Semiconductor (ON): Silicon Carbide Powering Electrification”.)

Aehr Test Systems

Aehr Test Systems (AEHR +3.67%)

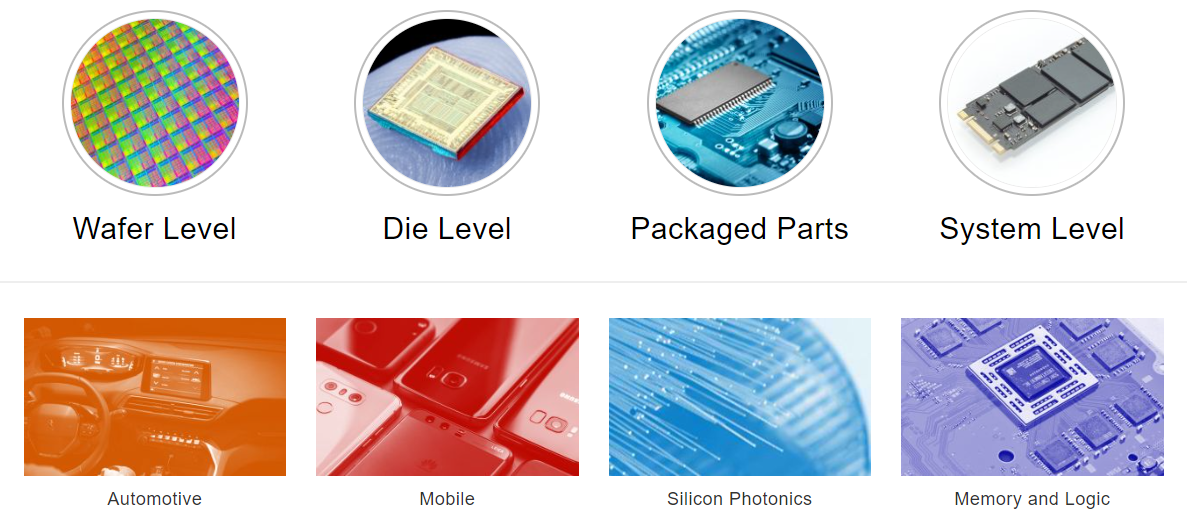

Aehr is a semiconductor company with a specialization in silicon carbide.

More precisely, the company is producing equipment for testing the silicon carbide wafers. This gives it a presence in the EV automotive sector, smartphones, computer chips, and photonics/telecommunication.

Source: Aehr

This makes Aehr a very niche and technical company and a crucial component of the supply chain. It claims to be “on the way to becoming the industry standard for a critical manufacturing step for silicon carbide power semiconductors.”

Aehr is also actively developing new markets, notably the gallium nitride burn-in market, used in high-power applications like photovoltaic inverters, making it present in both alternatives to silicon-based power electronics.

This gives Aehr a very diversified customer base, looking like the who’s who of the semiconductor industry and tooling industry, including TSMC, Texas Instruments, Seagate, Nvidia, Cisco, Qualcomm, and Bosch.

Source: Aehr

The company could benefit greatly from emerging new segments in the semiconductor industry, like silicon photonics.

In the meantime, by occupying a small and important niche (silicon carbide testing) inside another niche in the EV supply chain (silicon carbide power electronics), Aehr is well positioned to benefit from the growth in EV production volume, irrespective of the latest battery technology, car model, or change in charging plug standards.

After a massive surge in stock price in 2023, at the peak of enthusiasm for any EV-related stock, the company is now back to a more reasonable valuation and represents a “pick-and-shovel” option for investors in the silicon carbide sector.