Additive Manufacturing

Hands Like a Human: New Additive Manufacturing Helps Soft Robotics Go Real

Securities.io is not an investment adviser, and this does not constitute investment advice, financial advice, or trading advice. Securities.io does not recommend that any security should be bought, sold, or held by you. Conduct your own due diligence and consult a financial adviser before making any investment decisions.

In the rapidly evolving landscape of robotics, a new frontier is emerging that promises to reshape our understanding of the field: soft robotics. This innovative approach is making strides thanks to cutting-edge additive manufacturing techniques.

In this article, we explore the realm of soft robotics and examine how recent advancements in additive manufacturing are propelling this technology forward.

What is Soft-Robotics?

Soft robotics attempts to introduce technologies that more closely resemble the physical characteristics of living organisms, replacing the stiff movements we associate with robots. Considered a form of biomimicry where the conventional linear and stilted features of robotics move away to make place for sophisticated models, soft robotics imitate human, animal, and plant life.

Researchers estimate the soft robotics market to become a significantly large opportunity in the future, with its market size growing from more than US$770 million in 2022 to nearly US$22 billion by 2030. It would mean a phenomenal growth of close to 75% CAGR.

According to Harvard Biodesign Lab, which helps understand the technology of soft robotics as fluidic actuators having elastomeric matrices with embedded flexible materials like cloth, paper, fiber, and particles, soft robotics is to become popular for their lightweight, affordability, and easy customizability to a given application.

Some Applications of Soft Robotics

Harvard Biodesign Lab estimates there to be four million chronic stroke survivors with hemiparesis in the US today and another six million in other developed countries globally. These survivors often lose the motor abilities of their hands. Soft Robotics may help them address this challenge by helping to develop a modular, safe, portable, consumable, at-home hand rehabilitation and assistive device.

In the United States, the lifetime risk of developing heart failure is close to 20%. Leveraging the technology behind soft robotics, the Lab is developing a benchtop cardiac simulator and a Direct Cardiac Compression (DCC) device that will help treat heart failure.

With all these beneficial applications and more, Soft Robotics can play a significant role in patient rehabilitation and quality-of-life improvement efforts worldwide. Any technology that helps advance the cause of soft robotics is – therefore – a positive one. We will discuss some such manufacturing techniques today.

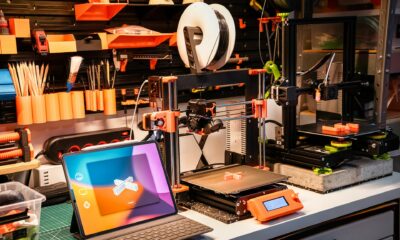

3-D Printing or Additive Manufacturing Technology in Soft Robotics

3D printing, also known as additive manufacturing, is about developing three-dimensional objects from a digital file. It is called additive manufacturing because of its inherent development process.

In the additive process of manufacturing, an object is developed by laying down successive layers of material until the final shape and form of the desired object are achieved.

Each of these layers is nothing but a thinly sliced cross-section of the desired object. Additive manufacturing differs from the traditional style of subtractive manufacturing, where parts of the desired shape and sizes are cut out of a large block of the source material.

3D printing or additive manufacturing usually involves a 3D model, a 3D software, and a 3D printer. The process has already found applications in the manufacturing of consumer products, industrial products, dental products, prosthetics, architectural scale models and maquettes, reconstructed fossils, replicas of ancient artifacts, reconstructed evidence in forensic psychology, movie props, and more.

Now, it has found usability in the more sophisticated field of soft robotics. ETH Zurich and a US-based startup, Inkbit, have jointly made it possible.

While Inkbit is an MIT spin-off, ETH Zurich's University of Science and Technology dates back to 1855, “when the founders of modern-day Switzerland created it as a center of innovation and knowledge.”

Click here to learn all about investing in 3D Printing/additive manufacturing.

The Technology in Detail

The Breakthrough

The breakthrough that the ETH Zurich and Inkbit's research has achieved is that it has expanded the scope of materials that can be used in additive manufacturing or 3D printing. While earlier, the technology was only limited to fast-curing plastics, now it has become suitable for slow-curing plastics as well. There are many advantages of this scope enhancement.

The Benefits

- Slow-curing plastics have enhanced elastic properties.

- They are more durable and robust.

- Slow-curing plastics make it possible to 3D print complex and more durable robotic elements.

- The technology is compatible with a variety of high-quality materials

- The scope enhancement makes it easier to combine soft, elastic, and rigid materials.

And finally,

- They match the requirement to create delicate structures and parts with cavities as and where desired.

The Application

With slow-curing plastics, it has become possible to merge the benefits of soft robotics and additive manufacturing and create a synergy that will benefit mankind for a very long time.

The researchers at ETH Zurich have successfully come up with a robotic hand that has all the qualities of human physiology, such as bones, ligaments, and tendons. Although made of different polymers, the final product could be made in one go.

According to researchers, this would not have been possible had they not been able to include slow-curing polymers. According to Thomas Buchner, a doctoral student in the group of ETH Zurich robotics professor Robert Katzschmann and the first author of the study:

“We're now using slow-curing thiolene polymers. These have very good elastic properties and return to their original state much faster after bending than polyacrylates.”

The inclusion of thiolene polymers has been game-changing for producing the hand by the soft robotics principles. Because the robotic hand is as soft as a real human hand, it has less injury risk and can handle fragile goods better.

To accommodate soft robotics and additive manufacturing in the same process, the researchers had to introduce some modifications to the 3D printing technology. They added a 3D laser scanner to the printing, which can immediately check each printed layer for potential surface irregularities.

The researchers also introduced a feedback mechanism to compensate for these irregularities. This mechanism helped make necessary adjustments to one layer, taking into account the unevenness, if any, of the previous layer.

ETH Zurich took the help of Inkbit, the US-based startup, to develop this printing technology.

Inkbit: The Printing Technology Startup

Founded in 2017 by Davide M. Marini, Javier Ramos, and Wojciech Matusik, Inkbit is a Series B startup based out of Medford, Massachusetts, United States. The purpose of the company is to create a next-generation additive manufacturing platform that combines 3D printing with machine vision. The company keeps innovating and developing new solutions in the area of 3D printing. For instance, during mid-November this year, it demonstrated the single-print fabrication of complex multi-functional systems and robots.

A week earlier, the company had introduced TEPU 50A, a new soft-medium durometer elastomer.

There are several other players in the space that Inkbit caters to. All of them together are trying to drive progress in soft robotics through new additive manufacturing techniques.

Companies With Transformative Additive Manufacturing Techniques to Help Advance Soft Robotics

#1. Flashforge

Recently, a 3D-printed modular soft gripper with highly conformal soft grippers was developed. The fingers were composed of positive-pressure soft pneumatic actuators along with a mechanical metamaterial. The metamaterial integrated a soft auxetic structure and compliant ribs. The 3D printer used in the process was a low-cost, open-source fused deposition modeling 3D printer from the house of FlashForge Corporation.

Established in 2011, Zhejiang Flashforge 3D Technology Co., LTD is one of the first professional 3D printing equipment and materials R&D and manufacturing enterprises in China. Flashforge products travel to nearly 100 countries and regions globally.

It has developed more than 600 brand dealers in more than 50 countries and regions domestically and abroad.

FlashForge USA focuses on making 3D printing widely accessible to institutions, architects, engineers, designers, industrial users, and the broad consumer and prosumer markets.

Estimatedly, Flashforge has a revenue of more than US$15 million, while FlashforgeUSA has more than US$7 million.

#2. NinjaTek

Among its many solutions, NinjaTek's Cheetah® 3D Printer Filament was used to create flexible, life-like bones for prosthetic hands. The finger design required embedding a flexible 3D-printed bone into a silicone mold to create a realistic skin-like texture and increase the robustness and strength of the fingers. The researcher team responsible for designing and developing the hand found NinjaTek's semi-flexible Cheetah TPU filament very useful in designing the prosthetic piece.

NinjaTek is a part of Fenner Precision Polymers. It produces speciality filament for end-users in the 3D printing industrial space. The company is now a Michelin Group Company.

Michelin Group registered more than 28.5 billion Euros in revenue in 2022, compared to a revenue of close to 24 billion Euros in 2021. The company's operating income as a percentage of its revenue was close to 12% in 2022.

#3. Fictiv

Another key player in this field is Fictiv, a company offering a comprehensive range of 3D printing services and demonstrating a strong commitment to advancing soft robotics. Their expertise is highly sought after, with large med-tech companies such as Medtronic utilizing Fictiv's innovative services.

Fictiv believes that soft robots are more adaptable and flexible. It can “better understand various handle designs and adapt its movements accordingly.” It also sees soft robots as more “pneumatically actuated to grasp objects, which allows for the easy addition of suction capabilities.”

In May 2022, Fictiv announced the closing of a $100 million Series E funding round. The round was led by Activate Capital, including new investors like the Angeleno Group, Cross Creek, and The Westly Group. Fictiv's other institutional investors include Accel, Bill Gates, G2 Venture Partners, and Standard Investments. The Series E funding brought the total investment in Fictiv to US$192 million since it started its operations in 2013.

3-D Printing or Additive Manufacturing Technology in Soft Robotics: What the Future Holds

3D printing or additive manufacturing is to become a key technology in soft robotics because of its high quality and the capability to print multiple materials at the same time.

Soft robots are made of fluids, gels, functional polymers, and other easily deformable materials, which help the robotic solution remain operational even when stretched and squeezed. Importantly, these materials are compatible with current 3D printing or additive manufacturing technologies, which are not only faster but also more reliable. However, to become universally adaptable, they would have to enhance their scalability.

Another advantage that the new additive manufacturing technologies have is their high specificity and ability to print the most complex shapes.

New additive manufacturing techniques are also useful when it comes to placing the power sources, which are an integral part of most of the newly developed soft robots. Furthermore, new 3D printing techniques help intelligently place them inside the soft robotic structures.

On the flip side, the currently available 3D printable soft materials have a significant tendency to deform under the normally used forces during the building process due to their own weight, necessitating the inclusion of support material. This challenge highlights an area ripe for further development. Addressing this, one of the solutions has emerged in the form of viscoelastic hydrogels, which can withstand pressures ranging from Kilopascals to Megapascals.

Recently, a research group has also successfully developed an omnidirectional technique that can print extremely soft materials like liquids that can be held in place through polymerization at a later stage.

Another research team, composed of students of the Delft University of Technology, has introduced another exciting feature. It has helped develop 3D printing technologies that can cast silicones in 3D-printed shells. The technique is low-cost and can help soft robotics claim new heights in the future.

With more research and scientific studies done on the subject, additive manufacturing will help soft robotics become super relevant in the field of medical and health sciences. It has already helped develop soft robotic 3D-printed gloves that are useful for those who suffer from limited hand function, local paralysis, and arthritis.

Scientists have also built prosthetic hands and 3D-printed soft robots with four legs that can walk on non-uniform and rough surfaces such as pebbles and sand.

Apart from their medical and health rehabilitation use, such soft robots can help in rescue operations or be used to collect sensor data from dangerous environments.

Summarily, the opportunities that new additive manufacturing techniques present in advancing the cause of soft robotics are enormous. Only it has to come out of the lab for large-scale case use for public good.

Click here for the top ten additive manufacturing and 3D printing stocks.